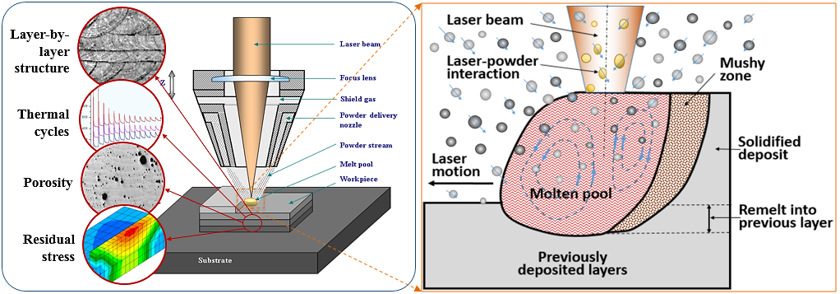

Directed Energy Deposition: Laser Engineered Net Shaping (LENS®)

| JMS uses a DED technique developed by Sandia National Laboratories called Laser Engineered Net Shaping (LENS), which can fabricate (traditionally) metal parts directly from CAD models. The process functions by using a laser to melt together newly deposited powdered material to the existing substrate of material. Due to the precise nature of additive manufacturing, the specifics of how builds are fabricated play a large role in the properties of the finished product. The JMS group explores in-depth the relationship between LENS processing parameters and the properties of objects created with them. Some of these processing parameters include: laser power (and thus, amount of energy used to fuse powder to substrate), laser scan speed (how quickly the powder—laser nozzle traverses the build’s surface in depositing each layer), hatch spacing regime (the geometry of the path followed by the nozzle in its deposition, i.e., the ‘hatch-space’ between each traversal of the nozzle), working distance (how far from the substrate the nozzle is held during deposition, which affects the dynamics of both the laser—material interaction and the geometry of the powder cone), and pulsed laser settings (to see whether or not non-constant energy application can impact the powder fusion behavior in a desirable way). Due to the high degree of complexity in the thermo-mechanical interactions between the laser beam, deposited powder, previously deposited layers, and the melt pool (where the substrate is melted by the laser to accept new powdered material), the mechanical properties of builds can vary significantly depending on the particular set of processing parameters used. Therefore, the JMS group expends substantial scientific effort in understanding all of the complicated relationships at play in AM so as to be able to precisely determine methods to reliably produce parts with favorable and consistent physical properties. |

Non-Conventional AM Materials

| A fertile area of AM research lies in expanding the scope of materials which can be fabricated in this manner. In addition to working with traditional engineering materials used in AM (such as stainless steel, titanium alloys, ‘inconel’ nickel superalloys, etc.), the JMS group is exploring the usage of other non-traditional materials in LENS manufacturing. Aluminum, for example, is notoriously difficult to process additively due to its very high reflectivity. Additionally, the group is pursuing additive manufacturing for ceramics, which can be hard to machine because of their hardness and high melting point. With intriguing potential uses in energy-based applications, high quality & reliable ceramic additive manufacturing is an exciting goal and ongoing project of the JMS group. |